AT (form factor)

Design

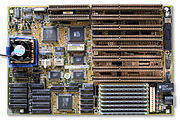

The original AT motherboard, later known as "Full AT", is 12 inches (305 mm) wide and 13.8 inches (350 mm) deep, which means it will not fit in "mini desktop" or "minitower cases". The board's size also means that it takes up space behind the drive bays, making installation of new drives more difficult. The power connectors for AT motherboards are two nearly identical 6-pin cables. Unfortunately, the two power connectors it requires are not easily distinguishable, leading many people to damage their boards when they were improperly connected. When plugged in, the two black wires on each connector must be adjacent to each other, creating a row of 4 black wires (out of the total 12) and a correct connection. Technicians developed mnemonic devices to help assure proper installation, including "black wires together in the middle" and "red and red and you are dead."

Variants

In 1985 IBM introduced Baby AT. Soon after all computer makers abandoned AT for the cheaper and smaller Baby AT, using it for computers from the 286 processors to the first Pentiums. These motherboards have similar mounting hole positions and the same eight card slot locations as those with the AT form factor, but are 2" (51 mm) narrower and marginally shorter. The size (220x330 mm) and flexibility of this kind of motherboard were the key to success of this format. While now obsolete, a few computers are still using it, and modern PC cases are generally backwards compatible to fit Baby AT.

In 1995, Intel introduced ATX, a modern form factor which gradually replaced older Baby AT motherboards. During the late 1990s, a great majority of boards were either Baby AT or ATX. Many motherboard manufacturers continued making Baby AT over ATX since many computer cases and power supplies in the industry were still compatible with AT boards and not ATX boards. Also, the lack of an eighth slot on ATX motherboards kept it from being used in some servers. After the industry adapted to ATX specifications, it became common to design cases and power supplies to support both Baby AT and ATX motherboards.

The ATX form factor is a replacement for the older AT and baby AT form factors. Invented by Intel in 1995, it incorporates the first major change in the layout of PC motherboards to occur in years. The ATX motherboard rotates the orientation of the board 90 degrees. This allows for a more efficient design, with disk drive cable connectors closer to the drive bays and the CPU closer to the power supply and cooling fan. All Intel motherboards currently produced are ATX motherboards. Generally speaking, an ATX motherboard is required to use the newest Intel processors. Because of this and the general improvements that ATX brings, the ATX form factor is the form factor of choice for both commercial mass-production systems and for home PC builders.

ATX motherboard and case design

The ATX case looks very similar to the baby AT case, except that the holes in back for ports and keyboard and mouse connectors have been altered to allow for the different design of the ATX motherboard. In particular, the ATX motherboard has integrated I/O ports mounted directly on the edge of the board. Most ATX motherboards have, from left to right, stacked keyboard and mouse ports, stacked USB ports, printer and game ports along the top, and two serial ports along the bottom. This design can differ based on the manufacturer of the motherboard. This allows for a much more effective use of interior case space, and decreases the number of cables and connectors that can become disconnected or damaged.

ATX cases often have more drive bays for a given case size. For example, a mid-tower ATX case will often have more available drive bays than a baby AT case of the same size. The ATX case design also generally provides easier interior access to expansion bays.

The ATX power supply is different in a number of important ways. ATX power supplies and motherboards function at 3.3 volts or lower, instead of 5 volts, reducing motherboard cost, energy consumption, and heat production. The fan on the power supply is reversed so that it blows air into rather than out of the case, which helps keep the case clean and reduces heat buildup. This is necessary due to the high heat produced by the new generation of Intel Pentium II/III and AMD processors. The ATX power supply is turned on and off using electronic signaling instead of a physical toggle switch. This allows the computer to be turned on and off using software control, thus improving power management and energy-saving features. Because of this, ATX power supplies must be matched with ATX motherboards.

BTX(Form Factor)

BTX (Balanced Technology eXtended) is a new personal computer form-factor that has been designed to replace the ATX case and motherboard layouts our computer components are currently built around. At the moment it is an Intel-only proposed standard, as AMD currently has no plans to support the BTX form-factor. There is no reason why it couldn't in the future though The form-factor of a computer affects the case layout, the positioning of components on the motherboard and the power supply positioning and connections. It allows motherboard, case and power supply manufacturers to know that their products will inter-operate with other parts designed to the same standard. BTX, proposed by Intel and recently ratified, makes some fairly radical changes to case and motherboard design in order to provide increased cooling for the components that need it most: the processor, chipset and video card. To put it simply, these components are moved so that they can all be effectively cooled by the airflow passing through the case. The case itself is modified so that front and rear vents are available to send the required airflow across the motherboard and out the rear of the computer. The rest of the motherboard components have also been shifted to accommodate all this positioning. Effectively, the BTX form-factor attempts to standardize case cooling so it can provide a steady flow of fresh air that modern components desperately need, while minimizing the amount of noise necessary to deliver it. The motherboard redesign will allow this to happen with a minimum of active cooling, with a single 'thermal module' both cooling the processor and creating the stream of air that will cool the other components. BTX Changes: Thermal Solutions and Motherboard The most obvious change to the motherboard is how the heatsink interfaces with it. The orientation of the processor heatsink has been altered from the standard downward facing fan/heatsink design to one that blows air through from side-to-side. Instead of the comforting, fan-topped hunk of aluminum or copper we've all become familiar with, BTX introduces something completely new, the 'thermal module.' The so called thermal module consists of the heatsink, fan, and fan duct. Dell, to name just one manufacturer, has long been using air ducts to reduce noise from inside the PC, while at the same time cooling its PC's internal components just as effectively. The thermal module takes this one step further. Combining a single large fan, a heatsink for the processor and some form of ducting to guide airflow, the thermal module will be the key for effective cooling of BTX systems.  For example, ATX cases can be designed to accommodate ATX motherboards, since according to the standard, the case manufacturers know exactly where the I/O ports are going to be, and where the PCI expansion ports need to be placed. Likewise, ATX motherboard manufacturers know how many screw holes to place in their boards and where they need to be positioned to fit ATX cases, etc.

For example, ATX cases can be designed to accommodate ATX motherboards, since according to the standard, the case manufacturers know exactly where the I/O ports are going to be, and where the PCI expansion ports need to be placed. Likewise, ATX motherboard manufacturers know how many screw holes to place in their boards and where they need to be positioned to fit ATX cases, etc.  Let's run through the actual changes that the BTX standard makes to traditional ATX components, as there are a few other developments to consider.

Let's run through the actual changes that the BTX standard makes to traditional ATX components, as there are a few other developments to consider.

COM Express is the PICMG industry standard for Computer-on-Modules, developed with embedded industry participation under the sponsorship of Intel, Kontron, PFU, and RadiSys.

The goals of the COM Express standards effort include the creation of specifications for small-form-factor modules to satisfy all performance segments of the embedded industry. For example, high-performance segments can use COM Express to replace PCI-X and AGP with PCI Express and replace parallel ATA with Serial ATA. COM Express also provides a bridge between legacy-free and legacy functions by incorporating optional PCI and IDE interfaces.

According to Wade Clowes, vice president and general manager of RadiSys Commercial Segment, "COM Express makes it an order of magnitude easier to configure a range of embedded products. RadiSys customers will be able to offer a line of products from low-end to high-end, using the same carrier board and swapping-out the COM module."

Functional Overview

Figure 1

COM Express board-to-board connectors consist of two rows of 220 pins each. Row AB, which is required, provides pins for PCI Express, Serial ATA, LVDS LCD channel, LPC bus, system and power management, VGA and TV-out, LAN, and power and ground interfaces. Row CD, which is optional, provides SDVO and legacy PCI and IDE signals next to additional PCI Express, LAN and power and ground signals.

COM Express provides support for:

- Up to 32 PCI Express lanes with 80-gigabit per second (Gbps) aggregate bandwidth

- External x16 PCI Express graphics

- Up to four Serial ATA-150 links with 600-megabyte per second (MBps) aggregate bandwidth

- Up to three 1-Gbps Ethernet ports, with provision for 10-Gbit Ethernet in the future

- Up to eight USB 2.0 ports

- Up to two channels of LVDS

- Up to two channels of Serial DVO

As shown in Figure 2, COM Express includes two module footprints, a compact Basic Form Factor measuring 125 mm x 95 mm and an Extended Form factor of 155 mm x 110 mm. These form factors share the same connector and signaling definitions and have overlapping mechanical assemblies. This makes it possible to interchange a Basic Form Factor module with an Extended Form Factor module, and vice versa. The Extended Form factor makes room for double the memory capacity and dual-channel memory configurations, in addition to larger processors and chipsets. Standardized height and heat spreaders further facilitate interchangeability between modules from different manufacturers.

Figure 2 COM Express footprint definitions, including Basic Form Factor (top) and Extended Form Factor (bottom)

The Extended Form Factor has a power budget of 160 Watts to support larger processors and chipsets. It also can accommodate dual-channel memory configurations. Standard height and heat spreaders facilitate interchangeability.

The form factor flexibility of COM Express enables developers to segment their designs for different classes of embedded applications, noted Kishan Jainandunsing, vice president of Technology and Business Development at PFU Systems. "The Basic Form Factor is extremely well suited for highly power sensitive, small devices such as portable applications for medical imaging and test and measurement. The Extended Form Factor is a good choice for mobile or stationary applications where performance is more important than low power dissipation, such as 4D ultrasound machines, arcade gaming devices, multimedia kiosks and electronic advertising billboards. Interchangeability between the two form factors is a bonus."

.jpg)

No comments:

Post a Comment